A cement plant that is over 56 years old has been ordered to relocate outside city limits. The plant has a number of production lines that have been added over the years. Only two lines remain fully operational, with a high output capacity of 10,000 tons each. In one of these lines, a fire breaks out in a packet conveyor system approximately 30 metres above ground level. The fire was noticed by ground traffic supervisor who managed to evacuate the affected area of the plant and call the civil defence authorities, who responded quickly and were on site within minutes.

CEERISK engineers were appointed to investigate the cause of the fire. Soon they were dispatched to the fire scene where they initiated an investigation starting with interviews of eye witnesses and maintenance engineers were responsible for inspecting the conveyor system on a weekly basis.

During the investigation, it was revealed that at first firefighters lacked proper equipment to reach the fire in the conveyor system, as it stood 30 metres above ground. They called backup crews from nearby stations who arrived after sometime. Crews battled the fire and managed to control it after few hours.

Despite the time that lapsed between the discovery of the fire and eventual suppression, the damage was quarantined to the top section of the conveyor system. Luckily, there was a limited amount of material that could burn, limiting the fire spread. Nevertheless, the heat caused by the fire was so intense that it rendered the conveyor system a total loss.

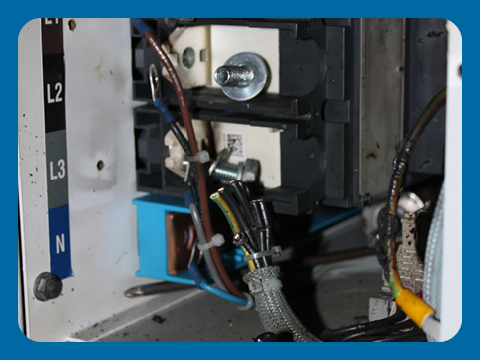

A detailed and thorough inspection of the scene was then conducted, during which CEERISK engineers identified relevant artefacts that were secured, removed and transported to CEERISK offices in the UK for further forensic examination and testing.

Based on the examination of the conveyor system, it was concluded that the seat of the fire was at the top of the conveyor run and involved the conveyor structure itself. Investigators identified multiple potential causes for the fire, including friction for poorly maintained mechanical parts and defective conveyor sections. The investigation is continuing where all hypothesis are being thoroughly explored and scrutinised to determine the root cause of the fire.

Only few weeks after this fire, another fire broke out in a different conveyor system in the same area within the plant. CEERISK engineers were again appointed to investigate the cause of the second fire, which caused significant damage to the largest production line in the plant. The conveyor system involved in the second fire was not the one in the first fire. Despite differences in design and specifications, the investigation is looking into similarities that may exist.