First published in My Expert Witness Magazine - Summer Issue no. 62

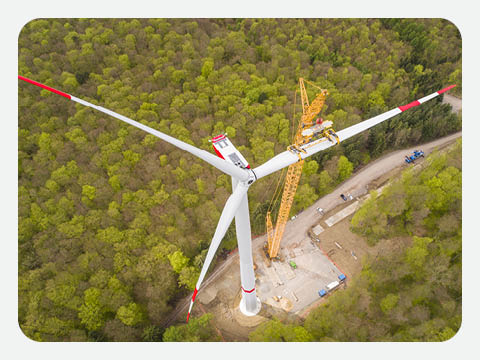

In 1991, the first offshore wind farm was built, with a generating capacity of 5MW. Today’s largest windfarm, Hornsea One, off the shore of Hull in the UK, boasts a generating capacity of 1.2 gigawatts (GW) from 174 wind turbines.

Technology has improved in the past thirty years, as has our experience in investigating failure incidents in offshore wind farms. Though failures of subsea cables are the costliest, the cost of damage caused by failures of other equipment in an offshore farm can climb quickly once access and accommodation costs are added in.

When investigating failures in offshore farms, few factors should be considered:

Loss of income

Failure of equipment, used to connect generated power to the grid, leads in most cases to turbine shut down and loss of income, as generated power can no longer be exported. This shut down can add up a significant amount to the overall loss caused by the failure.

High cost of incident investigation

The location of offshore wind farms increases access and accommodation costs. OEM engineers, independent experts and damage inspectors must be brought to the failure site where they need to be housed for the duration of investigation. In addition to the cost of special vessels, the overall logistical cost of investigations becomes significant.

Causes of Failure

Causes of failure fall into four categories: design failure, manufacturing defect, incorrect installation, and environmental conditions.

Design failure occur when poor design interacts with the harsh offshore conditions causing failure of equipment, subsea cables, terminations, joints, control systems including power conversion equipment.

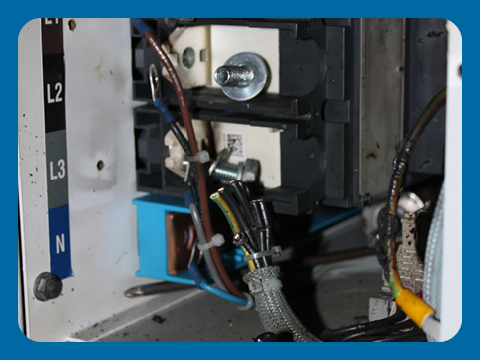

Manufacturing defects during the manufacturing of components result in latent damage such as voids in the insulation, loose solder joints, improper adhesion of layers in busbar systems, improper spacing, and others.

Installation failures result from stress on components, arising from incorrectly connections, improper coiling of cables, location errors, improper spacing and failure to support components in place.

Serial defect is a real problem

Design defect and manufacturing defect raise concern of serial losses in systems that may have not failed. If all components designed or manufactured in same inadequate way, some may fail, while other continue to operate with the latent failure for a limited time.

Availability of experts

Offshore failure incident require experts with not only the necessary subject expertise, but also the knowledge and experience of the special conditions in offshore farms. This is further complicated by the fact that before incident investigators can go offshore, they must have access and safety qualifications.

The challenge of unknown unknowns

As technologies continue to evolve and be deployed further away from shore, there remains a significant number of unknown unknowns that we are only finding out about after a significant incident occurs.