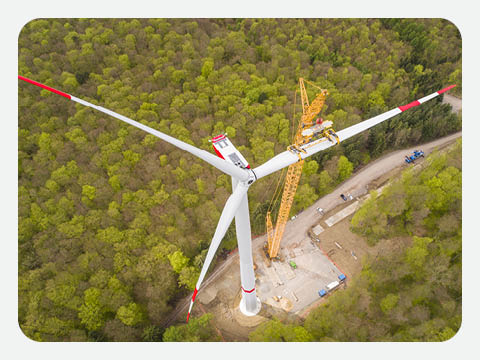

Whether it is an aviation accident or a broken turbine blade, mechanical failures are costly affairs resulting in expensive physical damage to the equipment involved and extensive business interruption.

Whether it is an aviation accident or a broken turbine blade, mechanical failures are costly affairs resulting in expensive physical damage to the equipment involved and extensive business interruption.

Investigating the cause of mechanical failures requires a deep understanding of machines and the operational environment where the machines are used, as well as an understanding of failure mechanisms and how to identify failures in different type of applications.

Our experts have investigated the root cause of mechanical failures in various numerous situations, including:

Our experts have investigated the root cause of mechanical failures in various numerous situations, including:

- Water escape from PRVs (Pressure Reducing Valves)

- Failure of steam turbine blades in power plants in several countries

- Failure of thrust bearing in a gas turbine

- Compressor failure in multiple applications including petrochemical plants

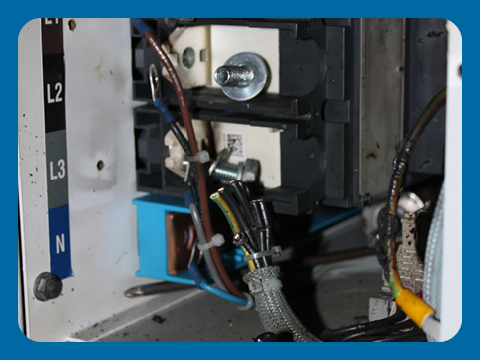

- Electric motor malfunction in different applications

- Circulation pump seizure

- Compression joint separation

- Flange seal leakage

- Failure of earth magnets in MRI scanners

- Heat exchanger blockage

- Valve and/or compressor cavitation/erosion

- Vibration induced failure

- Stress cracking of plastic valves and pipe fittings

- Push-fit joint failure

Our experts employ advanced mechanical testing techniques (including tensile, bending, and fatigue testing) to understand the behaviour of different material under different operating conditions. When necessary, we have partnered with specialised laboratories in leading universities around the world to facilitate the testing of different types of equipment.

Our extensive experience in developing and managing test protocols has allowed us to reach accurate conclusions in even the most complex situations. Courts in many jurisdictions around the world have relied on our expert reports and testimony to understand complex mechanical engineering matters at the heart of many disputes.