Corrosion engineering is the specialist discipline of investigating and managing corrosion in metals and non-metals, including ceramics. Our corrosion experts investigate the cause of corrosion and report on corrosion processes, including cracking, brittle fracture, crazing, fretting, and erosion.

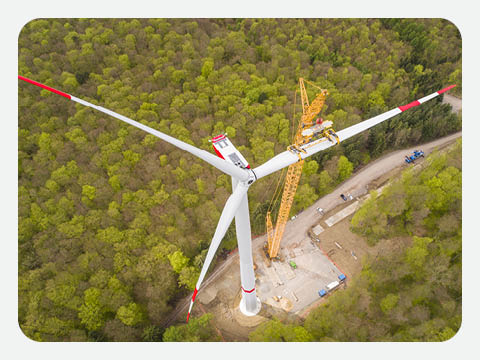

Our understanding of the corrosion process allows us to determine the root cause of failure in a variety of systems, including water systems, chemical pipes, offshore platforms, turbine blades, cranes on construction sites and equipment in petrochemical plants.

Examples of investigations carried out by our experts include:

- Microbiological induced corrosion

- Pin-hole corrosion of copper pipe

- Radiator corrosion

- Stress corrosion cracking of brass valves and pipe fittings

- System failures

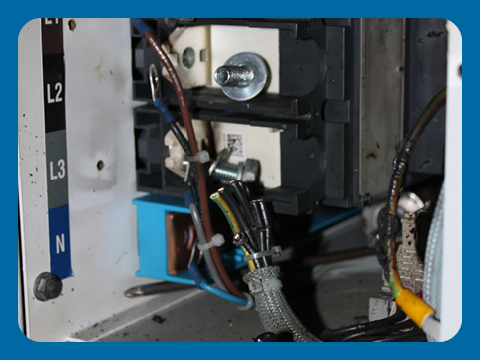

- Transformer failure

- Underfloor heating

Advice from our experts has been used by governmental departments in the UK as well as in other critical industries to investigate corrosion development in complex and sophisticated systems.

The investigation of corrosion failures is very complex and requires multidisciplinary testing and analysis to determine the root cause of failure. The use of highly sophisticated laboratory equipment is one way that our experts study and analyse the physical evidence presented to us in a given matter. Sophisticated equipment on its own cannot provide opinions to a high degree of engineering certainty. It is equally, if not more important, to have the correct experience and qualifications to be able to understand and analyse the laboratory findings of complex corrosion losses.