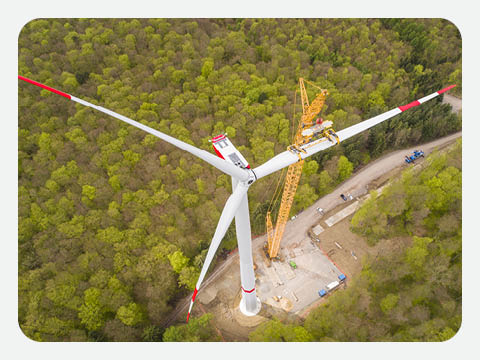

As companies struggle to improve their financial position under pressure from adverse economic conditions, new ways to maximise the available but limited resources are employed by more and more businesses. One way of stretching the resources available to manufacturers is extending the service life of plant and equipment by running them past its design life.

While equipment is being used beyond its designed service age, it is becoming harder to maintain as components are becoming expensive and scares. These conditions increase the likelihood of breakdowns with age and use. A survey by Morgan Stanley found that most industrial equipment in North America is, on average, over 10 years old. Not since 1938 have North American factories worked with such outdated equipment. The same conditions are found in the rest of the world, where equipment is being run longer and harder, while maintenance resources are being cut and squeezed.

Under current market conditions, insurers are finding that they need to extend cover to ageing plant and equipment to be competitive and to provide their clients with required certainty and business continuity. Insurers must be able to overcome new challenges arising from these conditions and to work carefully with clients to ensure adequate condition monitoring and maintenance programmes are in place.

Typically, ageing is simply defined in terms of time, describing plant and equipment that has reached the latter stages of its design life, whatever that is, as ageing equipment. This definition alone does not account for additional factors that may lead to accelerated deterioration of plant and equipment. It would be more accurate to define “ageing” in terms of the process of change in the properties of a material, a machine or equipment over a period of time. This definition of ageing allows us to associate it with the increased risk of damage or failure as a result of different factors, including time and operational conditions.

As equipment ages, it tends to fail more frequently, requiring more extensive maintenance and repair. Some of the factors that lead to equipment failure include external forces, environmental conditions (temperature and humidity), power quality, cleanliness, operating conditions and others. In general, factors that stress the materials used in constructing the equipment are factors that should be assessed to determine if the equipment is subject to accelerated ageing or normal deterioration with time.

As equipment ages, it tends to fail more frequently, requiring more extensive maintenance and repair. Some of the factors that lead to equipment failure include external forces, environmental conditions (temperature and humidity), power quality, cleanliness, operating conditions and others. In general, factors that stress the materials used in constructing the equipment are factors that should be assessed to determine if the equipment is subject to accelerated ageing or normal deterioration with time.

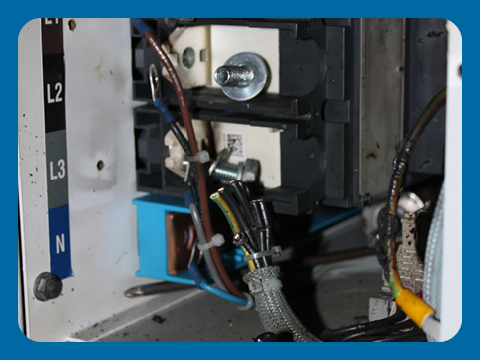

As electrical equipment age, they become inefficient and unsafe. Lack of good and thorough condition monitoring and comprehensive maintenance is a key reason why electrical equipment fails. Failure to follow manufacturer guidelines and procedures can lead to significant financial losses and injury to operators and users of electrical equipment.

Electrical equipment is typically installed and remains in location for the life of the facility. It’s typically located in remote spaces with limited access by employees. In addition, many facilities do not have current documentation of their electrical systems, like single-line diagrams that are necessary to identify the equipment and record its design specifications.

With the downsizing in labour forces there are fewer opportunities to do in-person inspections by qualified personnel. Depletion of expertise in many plants where older, experienced professionals are not being fully replaced by the new incoming workforce also presents a challenge to many operators.

Insurers need to be aware of the challenges associated with operating ageing electrical equipment and look for systems deployed by the operator to manage the risk of failure in ageing equipment. Thorough investigation of the condition monitoring systems and controls systems can support migration from time-based maintenance to condition-based, where maintenance cycles can be based on actual circuit conditions instead of specific time intervals.

Effective maintenance programmes can prolong the service life of equipment, but only if closely implemented and carried out by qualified personnel. Availability of replacement parts and system redundancies are also critical items that need to be investigated and properly assessed.