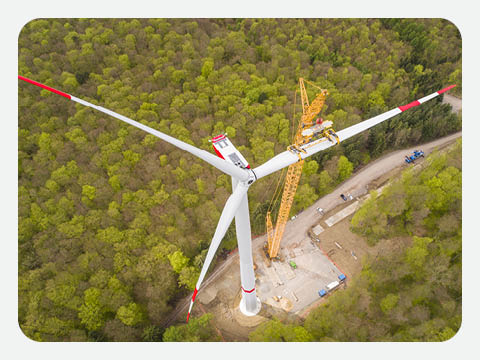

Steel is used in many applications. Different types of steel are manufactured which possess different properties, examples include carbon steels, alloy steels and stainless steels. The deployment of renewable energy projects around the world utilises a large amount of steel, as do many other civil engineering projects.

The steel industry covers both upstream and downstream industries, from mining to transport to processing in specialised industrial settings. Steel is also a widely recycled metal and does not live a cradle to grave life cycle.

Technical Expert Services

Disputes can arise at multiple points throughout the steel industry, from ore mining and refining to the utilisation of steel in manufacturing of products.. Understanding the scientific and technical processes that underpin this industry is necessary to resolve any disputes. From the chemical make-up of the material itself to the particulars of manufacturing projects, our Network of Experts are available to assist.

We are also familiar with the transportation requirements of steel, which plays a significant role in the industry.

Forensic Engineering

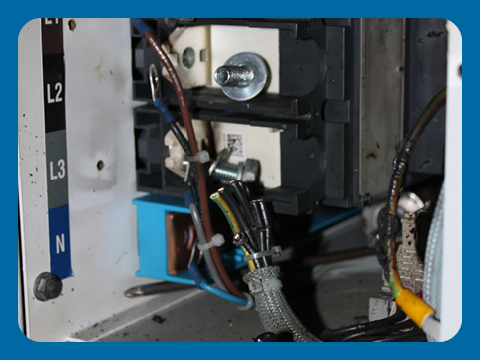

Incidents that occur within the steel industry are costly, including fires, machinery breakdown, and chemical spills. Our experts have investigated incidents across many industries including the steel industry and other metalworking plants. We are available and ready to assist in multiple capacities.

Reinstatement

Working with OEMs and service providers to come up with a cost-effective and efficient reinstatement options to minimise business interruption and to secure business continuity. We utilise our worldwide network of resources to identify like quality kind & replacement options.

Risk Management

The contemporary steel manufacturing industry is going through an economically challenging time. When making executive decisions about how to handle these difficulties, awareness of risks associated with the manufacturing process is critical for the survival of plants.

Our experts have worked within the steel industry and are aware of the specific risks unique to the industry. We have surveyed numerous properties and offered corrective recommendations whilst ensuring the proper measures are in place to reduce risk.

Some producers have chosen to idle parts of their plants to save expenses, with the intention of restarting them later. While often the correct choice, this brings with unique risks as restarting plants involves restart risks..

There are inherent concerns associated with the steel making process such as machinery breakdown and other damage that may arise should machinery not be appropriately monitored. Additionally, the presence of chemicals introduces further concerns regarding hazards, including explosion and fire risk.

With recent attention being paid towards climate change and the effect that industrial practices have on the environment, new regulations have been put in place to control emissions that are released into the atmosphere. We understand the new filtering technology used to ensure that all practices adhere to these regulations.