Plastic manufacturing companies use petrochemical products, including ethylene, propylene, butylenes, benzene, toluene and xylenes, to manufacture many different polymers. These manufactured goods include nylon, epoxy, resin, polyethylene, fiberglass, synthetic fibres, silicone and many other items used in many different applications, from everyday domestic use to packaging, building/construction, manufacturing and transportation.

The manufacturing of plastic involves raw products such as natural gas, oil and plants that are first refined and then treated with heat to create different polymers.

Forensic Investigation

Because the process of plastic manufacturing involves the use of raw combustible material as well as explosive materials, fires can occur. When this happens, the toxic smoke released into the air creates additional hazards that must be considered.

Incidents in plastic manufacturing plants present environmental hazards. Plastic fires generate and release pollutants, including microplastics, bisphenols and phthalates that can harm others.

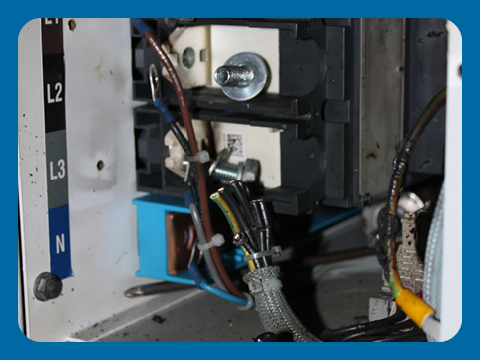

We also investigate the breakdown of machinery used in the production process.

Reinstatement

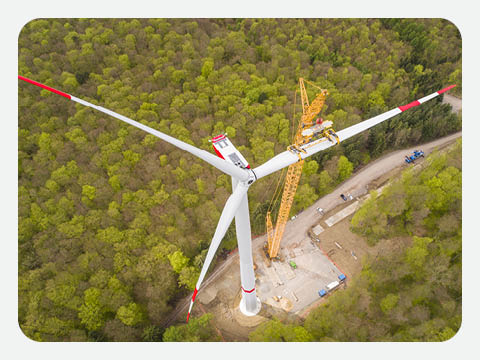

We work with OEMs and service providers to come up with a cost-effective and efficient reinstatement options to minimise business interruption and to secure business continuity to the insured. We utilise our worldwide network of resources to identify like quality kind & replacement options.

Risk Management

CEERISK experts have been instructed to carry out a number of detailed pre-risk analyses of plastic manufacturing plants, looking specifically at the risks inherent to the production process such as hazards associated with chemicals. We consider how these matters are addressed by management and provide recommendations to improve the overall risk profile.