Petrochemical plants convert natural resources into products that are used fora variety of applications These products include ethylene and propylene, olefins used in industrial chemicals and plastic products; benzenes, which are used in fuels; ammonia and methanol, are used in fertilisers; epoxy resins, used for flooring and insulating materials; plastics; soaps; detergents; synthetic fibres and rubbers.

Technical Expert Services

Disputes involving petrochemical plants require an understanding of plant engineering, including knowledge of plant processes, specialist machinery, equipment, and industry wide specialist operating procedures.

Our experts are experienced operators with first-hand experience in industry who understand complex operations as well as industry-wide best practices.

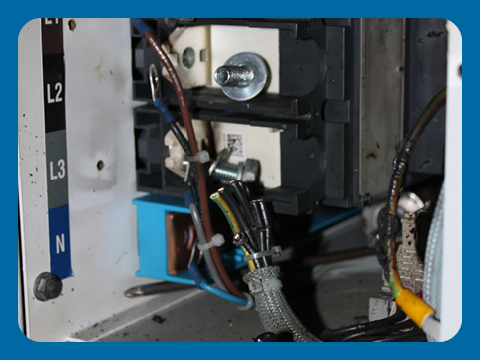

Forensic Investigations

Losses in petrochemical plants are often catastrophic and costly. When fires break out, the consequences are often complicated by industry-specific factors, including the presence of impure chemicals, maintenance and operation of specialist machinery, and human error.

Our experts around the world have experience investigating the types of losses that occur in petrochemical plants.

Risk Management

The operational environment requires a robust risk management plan to reduce the frequency and impacts of hazards. Specialist machinery in petrochemical plants requires a robust maintenance programme, and chemical hazards must be well-managed.

Our experts identify industry hazards and advise on the controls in place. We consider hazards associated with raw materials, machinery and machinery breakdown, power supply, corrosion and contamination.

We offer risk improvement recommendations and work with management to implement effective measures to reduce exposure to hazards and avert catastrophic and costly incidents.